The National Association of Manufacturers (NAM) released its Manufacturer’s Outlook Survey for the fourth quarter of 2022. It comes as no surprise that one of the main concerns of the manufacturing industry as we work our way into the first quarter of 2023 is potentially demanding economic conditions. With unease regarding inflation, leftover supply chain disruptions from the pandemic, and the workforce shortage, manufacturers’ confidence has declined.

Despite a decrease in manufacturers’ confidence, there are bright spots in the 2023 outlook. Over 63% of those surveyed see a solid demand for their company’s products.

Additionally, manufacturers plan to invest in:

- Capital spending on new equipment and technological investments

- Training for their existing workforce

- Hiring new employees

- R&D

- New buildings and improvements for existing structures

As business leaders move into 2023, three trends stand out as factors that could impact industrial business as we navigate through an uncertain economy.

Talent Management Strategy Implementation

In annual predictions, there is almost always a mention of the importance of employees and talent retention. In today’s workforce, the need to actively manage a strategy for the development and retention of people is more critical than ever. With the tight labor market continuing, recruiting, and retaining the right people continues to be a challenge.

“At American Cutting Edge (ACE), our people are the core of our business. And we hire our employees based on our core values. Curiosity and sharing knowledge is important to our organization. We encourage learning and promote an environment that encourages fairness, teamwork, and mutual respect among all colleagues. This mutual respect and fairness then naturally extends to how we treat our customers,” shares Director of Human Resources Yolanda Evers.

based on our core values. Curiosity and sharing knowledge is important to our organization. We encourage learning and promote an environment that encourages fairness, teamwork, and mutual respect among all colleagues. This mutual respect and fairness then naturally extends to how we treat our customers,” shares Director of Human Resources Yolanda Evers.

Recent data from Google Search Trends indicates that demand for warehouse and factory jobs is still climbing. If the number of employees who leave their jobs continues to decrease and demand for manufacturing jobs continues to rise, employers should be able to make a move to reduce overhead costs with more balanced compensation packages. This will help employers gain leverage in employment offer negotiations and help reduce overhead via fairer wages.

Taking into consideration that manufacturing is constantly evolving, it’s going to be critical for employers to continue to train new and existing personnel in new and expanded skills to keep up with industry demand. According to Evers, “training and planning for our current workforce to expand their understanding of technology is an investment we’re more than willing to make. We’re constantly looking for ways to develop and attract talent. Finding programs that help us keep ahead of the technology curve as much as possible helps us develop and attract future leaders who will help take ACE to the next level.”

The advancement of workforce skills helps employers reduce the skills gap while retaining valuable employees. Diversity, equity, and inclusion (DEI) initiatives will become increasingly important to get more people involved in the manufacturing sector. To help drive the DEI movement, the U.S. government has released The National Strategy for Advanced Manufacturing to “Expand and diversify the advanced manufacturing talent pool.”

Technology is the Key to the Future

Whether we’re talking about Industry 5.0, advanced ERP systems, or technological progress in general, it’s clear that there is no escaping the need for more advanced technology in manufacturing. McKinsey research predicts that by 2030, just seven short years from now, the share of physical and manual labor in the economy will have fallen by 27 percent. In its place will be skills that demand more technological and cognitive abilities.

Over the last several years, there has been an increase in digital investment and an acceleration in the adoption of emerging technologies. There is a direct correlation between those companies that have a higher digital maturity and resilience to difficult economic times and uncertainty.

McKinsey further predicts that in Europe and the United States, demand for physical and manual skills in repeatable and predictable tasks will decline by nearly 30 percent over the next decade. At the same time, demand for basic literacy and numeracy skills would fall by almost 20 percent.

When looking at the demand for technological skills (both coding and interacting with technology) should rise by more than 50 percent, and the need for complex cognitive skills is set to increase by one-third.

Technology will significantly shift the skill profiles of tomorrow’s jobs for employers and those seeking employment.

Supply Partner Relationships Will Be More Critical

Another common theme when we look ahead for a year is the importance of the supply chain. The global pandemic exposed the risks of relying too heavily on a few suppliers and amplified the need for a well-diversified sourcing approach.

Deloitte’s recent supply chain research shows that 80% of manufacturing executives have experienced a heavy to very heavy impact due to supply chain disruption in the past year to 18 months.

According to ACE’s supply chain director, Dan Brownfield, “We’re always going to live in a world where there is a potential for supply chain disruptions. No matter how well you plan or how diverse your sourcing strategy is, there’s always a risk of interruptions due to natural disasters, trade restrictions, and as we learned in the last couple of years, pandemics. There are some aspects of sourcing we simply can’t control.”

there is a potential for supply chain disruptions. No matter how well you plan or how diverse your sourcing strategy is, there’s always a risk of interruptions due to natural disasters, trade restrictions, and as we learned in the last couple of years, pandemics. There are some aspects of sourcing we simply can’t control.”

Brownfield continues, “What ACE has been able to do is mitigate the risk of supply chain disruption by being agile with strategic, proactive contingency planning, and supplier diversification. Over the last decade, we have developed a reliable worldwide network of suppliers in a variety of countries. This has helped us reduce delays due to port closures and raw material shortages. Because of our proactive approach to supply chain management, our partners were able to keep us stocked with the products our customers needed when they were needed the most. We didn’t have to worry about leaving our valued customers in a lurch without critical machine parts.”

Working with a true partner like ACE that can help navigate a disruption can make a difference. As businesses look forward to 2023, a continuing trend will be evaluating the cost of having multiple suppliers for increased agility and risk mitigation. The diversification of high-quality sources can make or break a company during uncertain times.

Moving Ahead

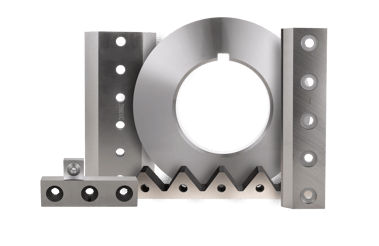

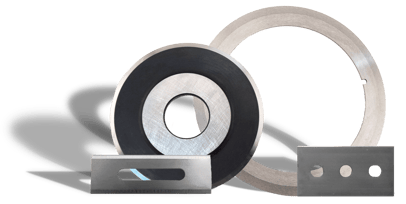

Reputation matters when you’re looking for an industrial knife, blade, and wear-part partner. Make sure you’re working with an organization that has the manufacturing and engineering experience you need but also, the business experience and acumen to successfully pivot when necessary, without sacrificing quality and customer service.

also, the business experience and acumen to successfully pivot when necessary, without sacrificing quality and customer service.

ACE was founded in 1965 based on the principle of putting our customers first. Our mission has evolved to the concept of making cutting effortless for our customers. To do so requires a great deal of attention to the backend processes, procedures, and relationships that we have developed over the course of our existence. Our commitment to our customers is to ensure that as times change, as an organization we’re ready to meet those changes and challenges with confidence so customers continue to receive the same level of outstanding service and quality products they’ve come to expect of us.

Take advantage of our years of experience and business knowledge by putting us to work for you.