No matter which brand of wood chipper you use in your tree care business, eventually you’re going to need to replace your blades. The question we receive most often is, “How often do I need to change my blades?” And the answer is it depends. It all depends on what you’re running through your chipper. Harder woods like oak are going to wear out your blades faster as are the things that may go into your wood chipper on a job that shouldn’t.

There are some tell-tale signs that you should look at your blades. Are you seeing irregular wood chips? Dull wood chipper blades shred and pull wood apart rather than cutting it. This creates poor-quality wood chips and regrinds.

This type of action puts more stress on the wood chipper engine, causing it to need more energy to force the blade through the wood. When more energy is needed to drive the engine, the chipper will be louder and will require increased horsepower. If this isn’t addressed, premature engine failure can result. And, remember that it’s important to change your hardware when you change your blades.

Regardless of when you need to change your wood chipper blades, ordering the right replacements the first time is important. The best way to make sure that you have the right blades is to consult your owner’s manual. If one isn’t available and you’re not sure of your chipper’s make and model, you’ll need to measure your blades.

Measuring your blades helps:

Reduce the risk of getting the wrong blades. Getting the right blades the first time your machine. Many wood chipper blades are very similar in appearance and in measurement. Subtle differences like the inside diameter of the holes can render your order of wood chipper blades useless. For your chipper to run safely and efficiently, you must have the right replacement knives in place.

Eliminate the need to return ill-fitting blades and pay restocking fees. Returning blades that aren’t correct is expensive. There are shipping fees back to the manufacturer, restocking fees, potential downtime for your equipment, or reduced chip quality while you wait for the correct blades. It’s a hassle on every front.

How to Properly Measure Your Wood Chipper Blades

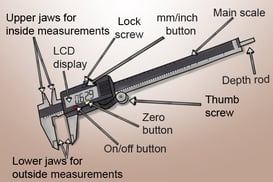

To accurately measure your wood chipper blades, you’re going to need a fractional tape measure and a caliper. In our demonstration video, we are using a digital caliper.

- Start by measuring the length of your chipper blades with your fractional tape measure. Be

certain to start with the metal tip of your tape measure to ensure accuracy.

certain to start with the metal tip of your tape measure to ensure accuracy. - Next measure the width using your fractional tape measure. Again, be sure to start measuring at the metal tip.

- To measure the distance between holes in your chipper blade, you’ll need to trade your tape measure for a caliper. Turn on your caliper, if it’s electronic, and insert the lower (sometimes called outer) jaws of the caliper into two holes. Once the jaws are in the holes, tighten them to get an accurate reading.

- Move on to measure the outside of the hole by laying the lower jaws of the caliper flat on the bottom of the blade. Adjust to ensure an accurate measurement.

- Flip the blade over to measure the inside of the hole using the upper jaws of the caliper. Insert the upper jaws of the caliper into the hole and extend them to allow for measurement of the entire space.

American Cutting Edge provides blade measurements in the product details section of their website for every blade to make finding the right blade the first time effortless. Many of our replacement wood chipper blades are available in convenient kits that provide everything tree care professionals need to change their blades including the correct hardware for the job.

Don’t forget about the ACE Best Chipper Product Price Guarantee.