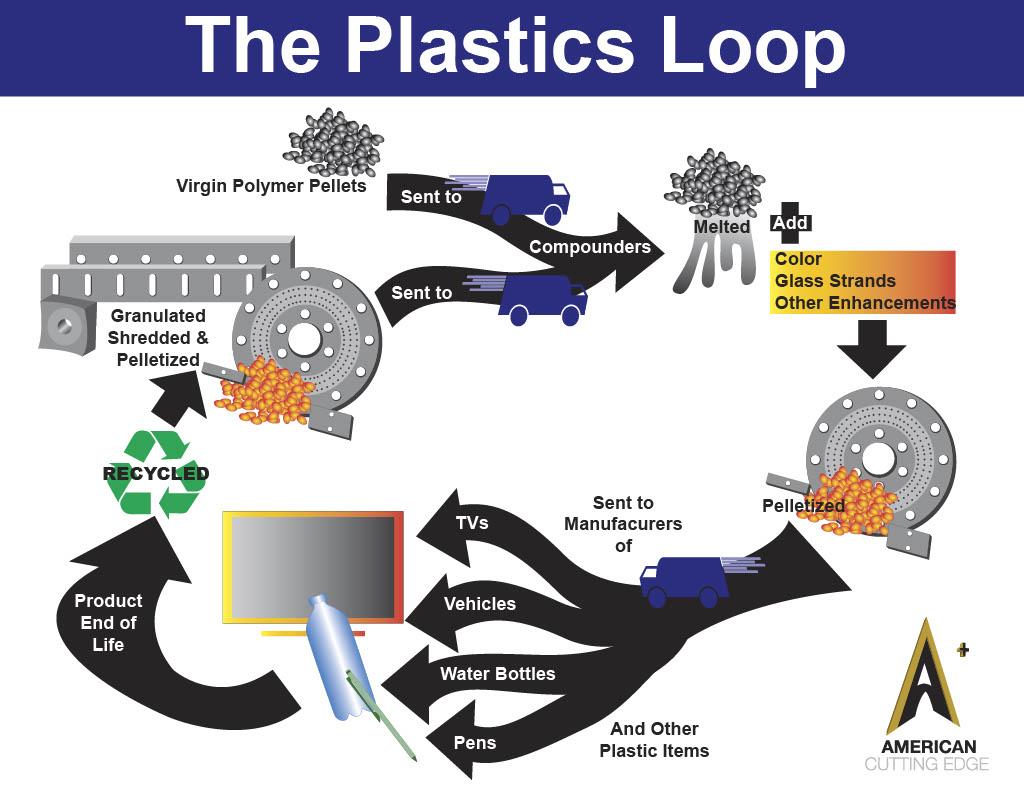

One of the goals of the plastics industry is to close “the loop” of plastic production to increase the use of existing materials and significantly reduce waste.

There’s no doubt that modern society is built for convenience. A big part of that convenience is single-use plastics. Whether we’re taking snacks to a ball game or grabbing bottled water at the drive-thru, plastics are everywhere. Plastic is cheap, can be used in unending applications, and is readily available.

The Plastic Problem

According to the latest research, for every person on the planet, there are 21,000 pieces of plastic in the ocean. around 137 million tons of single-use plastics were produced from fossil fuels in 2021, and it is expected to rise by another 17 million tons by 2027. 91% of plastic waste has been landfilled or burned or found its way into our seas. Only 9% has been recycled.

expected to rise by another 17 million tons by 2027. 91% of plastic waste has been landfilled or burned or found its way into our seas. Only 9% has been recycled.

The issue of plastic waste isn’t just in the difficulty in disposing of it but also in how plastics are created. Plastics are mostly made from raw materials like natural gas and oil, which are refined into ethane and propane. Ethane and propane are then treated with heat in a process called “cracking” which turns them into ethylene and propylene. These materials are combined to create different polymers, which hook together like beads on a string. Its name, polypropylene, literally means “many propylenes.”

Bioplastics

To address the environmental problems created by the production and disposal of plastics, the industry is exploring new methods of developing plastics. Bioplastics look, feel, and perform like plastic, but they get their shape and sturdiness from renewable sources – like corn starch, sugarcane, and plastic-producing microorganisms rather than petroleum. While bioplastics address the production problems associated with using fossil fuels, it doesn’t solve the whole plastics problem.

Bioplastics are often perceived to be “compostable” or “biodegradable.” However, in truth, “Bioplastic” is an inclusive term that encompasses various categories of plastic that differ in manufacturing methods and how much of their content comes from renewable sources. That means that not all bioplastics are the same. Some are biodegradable, meaning they naturally break down into smaller molecules. Some are compostable and biodegradable in controlled environments.

an inclusive term that encompasses various categories of plastic that differ in manufacturing methods and how much of their content comes from renewable sources. That means that not all bioplastics are the same. Some are biodegradable, meaning they naturally break down into smaller molecules. Some are compostable and biodegradable in controlled environments.

Recycle

Despite the intention of bioplastics to be more environmentally friendly, bioplastics only dispose well under the right conditions. The best solution for end-of-life depends on the type of biobased and biodegradable plastic, the volume of the market, the application, and available collection methods.

There are three primary ways to dispose of bio-based plastic waste.

As previously mentioned, not all bio-based plastics are biodegradable. That leaves traditional plastics and packaging waste collection as an option for bioplastic disposal. The process for bio-based plastics and durable plastic products is the same.

Collect and Compost

Bioplastics that are compostable can be collected and composted through biowaste collection process. There are more steps to the collection and composting process where bioplastics are involved as outlined in the graphic below. It’s important to note that while bioplastics can be “compostable,” that doesn’t necessarily mean that they can be composted at home. In most cases, biodegradable plastics will only degrade in an industrial setting under specific conditions.

Incineration

Bio-based plastics that cannot be disposed of via normal recycling processes can still be used for energy. Waste incineration plants can capture carbon dioxide from incinerated bio-based plastics to create new bio-based products.

The Role of Industrial Machine Knives and the Plastics Loop

Regardless of which Plastics Loop is required, industrial dies, knives, and blades are necessary at every single stage from the creation of virgin material, compounding of pellets and converting of pellets into sheet and/or film or other plastic products to the granulating, shredding, and pelletizing at the end of a product’s life. (Or scrap from the manufacturing process). American Cutting Edge engineers a cutting solution for each stage of the Plastics Loop.

sheet and/or film or other plastic products to the granulating, shredding, and pelletizing at the end of a product’s life. (Or scrap from the manufacturing process). American Cutting Edge engineers a cutting solution for each stage of the Plastics Loop.

Why ACE?

ACE has over 58 years in the industrial knife manufacturing business and understands every stage of the Plastics Loop. This provides us with unique insight and knowledge that few suppliers can offer. With advanced metallurgy and engineering experience, we know exactly how blades respond to plastic materials of all types regardless of their origin. Not only that, but ACE also has a firm understanding of how the changes that occur to this material throughout the Plastics Loop drive corresponding changes to blade materials. That's insight customers just can't gain anywhere else.

Contact ACE today to learn more about how we can help you with your industrial knives and blades.

.jpg?width=3033&height=2569&name=the%20bioplastics%20loop%20(002).jpg)