The Manufacturer’s Outlook Survey was just released by the National Association of Manufacturers (NAM) for the fourth quarter of 2023. Once again and without surprise, one of the main concerns of the manufacturing industry as we work our way into the first quarter of 2024 is potentially demanding economic conditions.

Even with a decrease in manufacturers’ confidence, over 66% of those surveyed see solid demand for their company’s products. Workforce challenges continue to be a concern, with 71% of manufacturers having trouble attracting and maintaining qualified candidates.

2024 industrial manufacturing focal points include but are not limited to:

- Talent attraction and retention

- Digital technologies

- Supply chain strategies

- Sustainability and movement to the lowest carbon emissions possible

Three of these focal points stick out the most to American Cutting Edge and our business strategy as we approach 2024.

Talent Attraction and Retention

Like in 2023, stocking the organization with qualified talent is critical. In a recent survey conducted by the National Association of Manufacturers (NAM), almost three-quarters of surveyed manufacturing executives feel that attracting and retaining a quality workforce is their primary business challenge.

Beyond hiring the right people, the trend in 2024 is to build a resilient workforce. Labor shortages and skill gaps have continued to plague organizations since the global pandemic. Active management of a strategy for developing and retaining people is critical. Tapping into the knowledge of retirees and long-term employees to bring newer and younger associates up to speed is one way to close the experience gap while transferring and documenting institutional knowledge so it is accessible to all.

“Our people are the core of our business. We hire our employees based on our core values. Curiosity and sharing knowledge are important to our organization. We fully support employees' learning and promote an environment that encourages fairness, teamwork, and mutual respect among all colleagues. “This mutual respect and fairness naturally extend to how we treat customers,” shares Director of Human Resources Yolanda Evers.

sharing knowledge are important to our organization. We fully support employees' learning and promote an environment that encourages fairness, teamwork, and mutual respect among all colleagues. “This mutual respect and fairness naturally extend to how we treat customers,” shares Director of Human Resources Yolanda Evers.

The advancement of workforce skills helps employers reduce the skills gap while retaining valuable employees. Diversity, equity, and inclusion (DEI) initiatives will become increasingly important to get more people involved in the manufacturing sector. To help drive the DEI movement, the U.S. government has released The National Strategy for Advanced Manufacturing to “Expand and diversify the advanced manufacturing talent pool.”

Digital Technologies

The need for advanced technology in manufacturing is a constant these days. With the advent of smart factories and the incorporation of AI into manufacturing processes, technology is more important than ever.

Blending our physical world with the virtual world has created an opportunity for the industrial metaverse to help drive collaboration and accelerate problem-solving. The industrial metaverse is the blending of technologies that offers a world where the real and digital worlds are always linked in an immersive environment of real-time collaboration. According to Siemens CEO Barbara Humpton, “In a digital environment, we have the ability to build, experiment, and virtually use the forces of nature on something before it even exists and then make a decision about what we actually want to build in the real world.”

technologies that offers a world where the real and digital worlds are always linked in an immersive environment of real-time collaboration. According to Siemens CEO Barbara Humpton, “In a digital environment, we have the ability to build, experiment, and virtually use the forces of nature on something before it even exists and then make a decision about what we actually want to build in the real world.”

Whether we’re talking about Industry 5.0, advanced ERP systems, or technological progress in general, there is no escaping the need for more advanced technology in manufacturing. McKinsey research predicts that by 2030, six years from now, the economy's share of physical and manual labor will have fallen by 27 percent, replaced by roles that demand more technological and cognitive abilities.

Technology will significantly shift the skill profiles of tomorrow’s jobs for employers and those seeking employment.

Supply Chain Reassessment

The supply chain continues to hold an important place in business. With the global pandemic still visible in our rearview mirror, there is still a need for continuous supply chain monitoring, management, and improvement. Emerging technologies don’t just apply to factory operations. The industrial metaverse also promises supply chain management freedom from deep-rooted organizational silos and enterprise systems that inhibit growth.

systems that inhibit growth.

Deloitte’s recent supply chain research shows that 80% of manufacturing executives have experienced a heavy to very heavy impact due to supply chain disruption in the past year to 18 months.

ACE’s supply chain director, Dana Smith, says, “Supply chains have faced a decade of disruptions. The risk of interruptions always exists, from the global pandemic and China-USA trade war to the Russian-Ukrainian war and other geopolitical volatility. There are some aspects of sourcing we can’t control.”

Smith continues, “ACE mitigates the risk of supply chain disruption by being agile with strategic, proactive contingency planning and supplier diversification. We have a reliable worldwide network of suppliers in a variety of countries. This allows us to reduce delays due to port closures and raw material shortages. Our partners keep us stocked with the products our customers need, keeping their lines running with the critical parts they require.”

Having a partner who can navigate a disruption makes a difference. As businesses get deeper into 2024, they will evaluate the cost of having multiple suppliers for mitigation of risk. The diversification of high-quality sources can make or break a company during uncertain times.

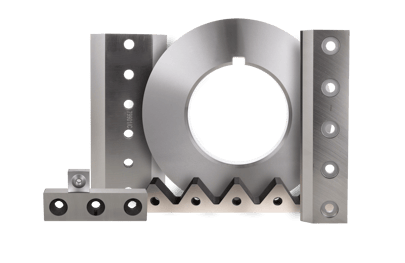

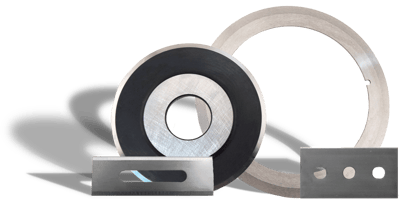

Beyond the Trends

Having a trusted source for your industrial knives, blades, and wear parts is important. Make sure you’re working with an organization with the manufacturing and engineering experience you need and the business experience and acumen to successfully pivot, when necessary, without sacrificing quality and customer service.

working with an organization with the manufacturing and engineering experience you need and the business experience and acumen to successfully pivot, when necessary, without sacrificing quality and customer service.

American Cutting Edge has been putting customers first since 1965. Our mission has evolved to the concept of making cutting effortless for our customers. Doing so requires a great deal of attention to the backend processes, procedures, and relationships we have developed while doing business.

As times change, our commitment to our customers is to be ready and able to meet changes and challenges confidently. In doing so, our customers will continue to receive the same level of outstanding service and quality products they’ve come to expect of us.

Take advantage of our years of experience and business knowledge by putting us to work for you.