Tree care professionals like you have a lot of things to think about. You shouldn’t have to spend a lot of time thinking about your chipper blades and how your blades contribute to helping you maximize production from your chipper. At American Cutting Edge, we spend a lot of time working one-on-one with our customers to ensure that they have the right blades exactly when they need them.

As a result, we receive a lot of different questions about everything from pricing and availability to chipper maintenance and hardware replacement. In this blog post, we'll explore some of the more frequent inquiries we receive including:

- What goes into the cost of replacement wood chipper blades?

- Do I have to order replacement blades from the OEM?

- How often should wood chipper blades be replaced?

- How can I tell when it’s time to change my wood chipper anvil?

- Do I need to change my hardware when I change my chipper blades?

What goes into the cost of replacement wood chipper blades?

Pricing on any industrial knife or blade can be influenced by a number of factors. Some, like the type of steel used to make the blade are more obvious. Blades made from different raw materials have different prices. The price of steel greatly influences the cost of your replacement blades. During times when the price of steel is lower, you might be able to find wood chipper blades that are less expensive.

prices. The price of steel greatly influences the cost of your replacement blades. During times when the price of steel is lower, you might be able to find wood chipper blades that are less expensive.

One overarching business function that some may not realize impacts the cost of the end product is supply chain. When was the last time you thought about your supplier’s supply chain? We’re going to guess that you may never have thought about it. Yet, supply chain and the relationships your vendor/partner has with their supply chain can make a tremendous impact on pricing. Why is that?

Those who manage the supply chain of a business handle the entire production flow of a good or service — starting from the raw components all the way to delivering the final product to the consumer. If that sounds like a pretty important job, it’s because it is. Supply chain managers have a lot of responsibility and are often to be the primary driver of product costs, inventory, and even customer service. They’re the behind-the-scenes business people who get the products customers need from suppliers from the procurement of raw materials to finishing the edge on the blade and getting it into stock on ACE’s warehouse shelves so you can buy it.

If your supplier doesn’t have solid supply chain relationships and a diverse network, getting high-quality blades in the quantities needed by customers is going to be a lot more difficult. The more difficult it is for a supplier to source the products you need, the more the products cost.

blades in the quantities needed by customers is going to be a lot more difficult. The more difficult it is for a supplier to source the products you need, the more the products cost.

American Cutting Edge understands the importance of delivering an outstanding product at a fair price to our customers. To make sure that you're taken care of at every turn, we offer the Brush Chipper Blade Price Guarantee. American Cutting Edge customers get the best online price every time.

Do I have to order replacement blades from the OEM?

In short, the answer is, “No.” You do not have to order replacement blades for your wood chipper directly from the OEM. OEM replacement blades are those that are sold by the original manufacturer of your wood chipper. Many tree care professionals don’t realize that they have a choice when it comes to replacing their blades and wear parts including hardware for their wood chipping equipment. With that being said, there’s a lot more to finding a reputable and quality industrial knife manufacturer to supply your replacement blades.

wood chipper. Many tree care professionals don’t realize that they have a choice when it comes to replacing their blades and wear parts including hardware for their wood chipping equipment. With that being said, there’s a lot more to finding a reputable and quality industrial knife manufacturer to supply your replacement blades.

When choosing a supplier for your chipper blades, it’s important to consider whether the organization follows the OEM knife or blade prints to the exact specification. Experienced manufacturers have a qualified engineering department that has developed a replacement blade with the exact tolerances of the OEM style blade. Even the slightest deviations can affect the fit and wear of the blade, causing an increased risk for premature chipping.

In some cases, a skilled industrial knife provider can create an OEM compatible knife that exceeds the OEM standard. Following the OEM drawings doesn’t mean your industrial blade manufacturer can’t get creative when you require a higher level of blade performance. It’s important to remember that you have options that can reduce costs and provide better productivity and outcomes.

How often should wood chipper blades be replaced?

We wish there was a hard and fast rule to answer this question. But, the fact is that it all depends on what you’re running through your chipper. Harder woods like oak are going to wear out your blades faster as are the things that may go into your wood chipper on a job that shouldn’t.

are the things that may go into your wood chipper on a job that shouldn’t.

It’s easy to throw things into the chipper when you’re doing storm clean up that might not be part of a normal job. We’re talking about things like telephone poles, building materials with metal bracing and things like that.

There are some tell-tale signs that you should take a look at your blades. Are you seeing irregular wood chips? Dull wood chipper blades shred and pull wood part rather than cutting it. This creates poor quality wood chips and regrinds. When this happens, it puts more stress on the wood chipper engine, causing it to need more energy to force the blade through the wood. When more energy is needed to drive the engine, the chipper will be louder and will require increased horsepower. If this isn’t addressed, premature engine failure can result.

How can I tell when it’s time to change my wood chipper anvil?

If there was one question we’d like to be asked more often, this could be it. Tree care professionals are more than aware of the need to change their wood chipper blades but fewer pay attention to their chipper’s anvil. As one of the more neglected parts of the wood chipper, your anvil should be high on the maintenance list right next to wood chipper blades. We always recommend that customers consult their wood chipper equipment manual to see what the OEM says about timing for anvil replacement. However, as a rule of thumb, we find that customers typically have an anvil change for every three to four chipper blade sets replaced.

The anvil is a stationary metal bar mounted to the chipper’s housing that supports the end of the logs as the chipper knife cuts them. Much like wood chipper blades, the number one symptom of a dull anvil is poor chip quality.

If your blades are new or have been recently sharpened and you see the following, it could be time to look at a new anvil.

-

- Stringy slivers in the chip

- Too much dust

- Uneven chunks

Do I need to change my hardware when I change my chipper blades?

The answer to this question is, "Yes!” Your chipper blades aren’t the only thing that take a beating when you’re out there processing tree limbs and branches. The hardware that secures the blades and keeps everything mounted safely in your chipper also get rattled with continued use and stress as you chip. This vibration and wear and tear can cause stress fractures in the hardware, looser fittings, and improper fit which require them to be discarded with every wood chipper blade replacement.

you’re out there processing tree limbs and branches. The hardware that secures the blades and keeps everything mounted safely in your chipper also get rattled with continued use and stress as you chip. This vibration and wear and tear can cause stress fractures in the hardware, looser fittings, and improper fit which require them to be discarded with every wood chipper blade replacement.

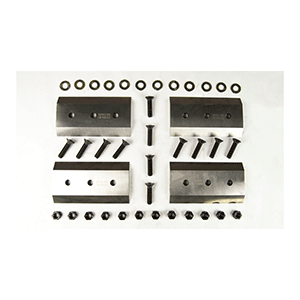

American Cutting Edge offers convenient wood chipper blade replacement kits that include everything you need to replace your blades from the knives themselves to the hardware so you are able to safely install everything without concern about if you've got the right nuts and bolts on-hand.

Need more information about how to safely change your wood chipper blades, check out this video and previous blog post.

Maximize the profit from your tree care business by finding the right supplier that is able to provide not only high-quality OEM compatible blades when you need them but that is also a true partner with cost-effective pricing.

If you have questions about your wood chipper replacement blades, anvil, wear parts, or what you should look for in a supplier, please tap into our 55 plus years of industrial knife manufacturing experience for more information today.