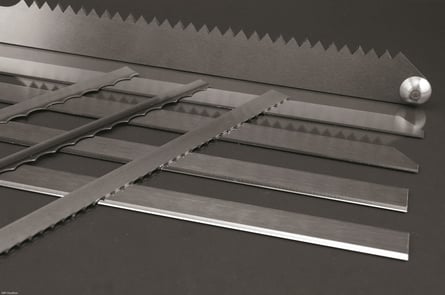

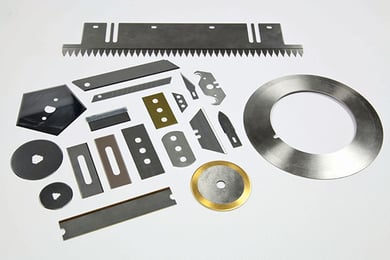

Packaging, Food Processing, and Food Packaging Knives

Most industrial food processing and packaging operations choose their industrial knife and blade supplier based on the cost of their products. There’s a lot more to this big decision than just the price tag of the product offering.

In this week’s blog, we’re talking with Heather Vreeland. Heather is product manager for ACE’s line of packaging machine blades and knives including fresh and dry food packaging.

According to Heather, the tight tolerances necessary for food processing applications and packaging lines mean that quality matters more than ever when choosing your supplier. “There’s no question that the quality of blade or knife makes all the difference in any cutting operation. The ability to maintain a sharp cutting edge and blade stability can make or break a production facility whether they’re processing meat, vegetables, packaging dry goods, or fresh food,” says Vreeland.

“Of particular importance is blade material when it comes to food processing. Making certain that food-grade materials, coatings, and oil are used is critical. Blades have to be stable to ensure that no chipping, breakage, or blade artifact is getting into the food being processed. I’ve always considered blade quality to be one of the best ways to mitigate risk and avoid costly recalls and reputational damage,” continues Vreeland.

“An organization with an in-house engineering team that truly understand cutting applications can review blade failures, troubleshoot the production line, evaluate materials and get to the root of the problem quickly. Sometimes there’s an opportunity to increase efficiency and reduce wear by switching the material from carbon to stainless steel depending on what’s being processed. There have been times when our team has reviewed video footage and times when on-site visits have been more appropriate. Other times, we've looked over drawings and even the failed blade itself. It depends on the scope of the problem. For some of our customers’ more complicated challenges, we’ve even pulled engineering in to make modifications to existing blades. Regardless of proximity to the customer, our goal remains the same and that’s to work in partnership with our customers to make cutting more effortless and more profitable for them,” she continues.

troubleshoot the production line, evaluate materials and get to the root of the problem quickly. Sometimes there’s an opportunity to increase efficiency and reduce wear by switching the material from carbon to stainless steel depending on what’s being processed. There have been times when our team has reviewed video footage and times when on-site visits have been more appropriate. Other times, we've looked over drawings and even the failed blade itself. It depends on the scope of the problem. For some of our customers’ more complicated challenges, we’ve even pulled engineering in to make modifications to existing blades. Regardless of proximity to the customer, our goal remains the same and that’s to work in partnership with our customers to make cutting more effortless and more profitable for them,” she continues.

Another important factor to keep in mind is inventory. Not all suppliers have a supply chain that’s able to keep their customers stocked with the right blades when the need arises or when priorities shift in their operation.

“One of the things I’ve always appreciated about being a part of the ACE team is the global supply chain our organization has developed over the last 55 plus years. We’re very fortunate to have solid relationships with sources around the globe so that we’re less likely to be impacted in the event of an unforeseen economic crisis, natural disaster, or global event like the coronavirus pandemic. Manufacturers without a rock solid supply chain struggled when ports closed and shipments were stuck on the docks or on the water waiting to come into port. ACE was able to continue to ship blades and knives to customers who were in desperate need as consumer behaviors shifted to cooking at home, driving an increase in demand for food,” shared Vreeland.

“I’m thrilled to be part of a thriving business where I can apply my knowledge of machine knives for automated packaging machines and food processing blades. The future at ACE is bright and I’m happy to be a part of it,” concluded Vreeland.